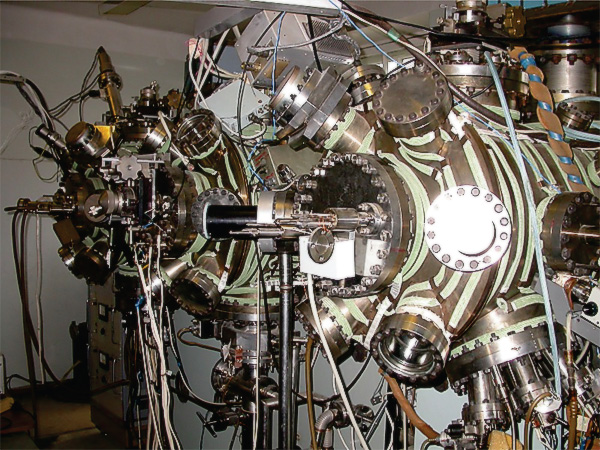

Angara Modular Molecular Beam Epitaxy Facility

Developed at the Rzhanov Institute of Semiconductor Physics, Russian Academy of Sciences, Siberian Branch

Specification

The facility comprises three technological modules for

- substrate preparation and analysis;

- epitaxy of semiconductor compounds;

- epitaxy of elementary semiconductors, metals, and dielectrics.

The mechanical vacuum system of the facility consists of the substrate loading/unloading module, substrate transport module, forepumping system, and ultra-high vacuum pumps.

Substrates up to 60 mm in diameter are loaded in any of the three chambers and unloaded after film (structure) deposition through a vacuum lock system by two- and five-step manipulators. The substrate preparation and analysis module is equipped with an ion gun for final ion etching and Auger depth profiling of substrates. The chamber for epitaxy of semiconductor compounds contains six thermal evaporators. The chamber for epitaxy of elementary semiconductors, metals, and dielectrics contains two thermal evaporation crucibles and two electron beam evaporators.

Residual gas content and molecular beams in the growth chambers are controlled by МХ-7304 mass spectrometers. Substrate purity and structure and thickness of a growing film are controlled by fast electron diffractometers. The chamber for substrate preparation and analysis is equipped with an Auger spectrometer for depth profile analysis of substrate and film chemical compositions. Optical parameters of synthesized structures are determined during the growth using an LEF-751М ellipsometer.